THE COLT MARK III

THE TROOPER MARK III

"J" FRAME

By the later 1960's Colt's revolvers were becoming too expensive and labor intensive to maintain profitability against competitors.

The old Colt designs required extensive labor by Master assemblers to build the complex hand fitted actions.

This was pricing Colt out of the market so they began designing an entirely new action unlike anything offered before by any gun maker.

This new design was to be a replacement for the old Colt medium frame revolvers. Just as Colt had offered everything from service type revolvers to target revolvers in the medium frame, this new design would offer new replacements for those models.

The new frame type would be named the Colt "J" frame, Mark III

The design was a totally new concept with nothing in common with the older Colt design.

Instead of the intricate old design using flat springs, the new models would use coil springs and a revolutionary "transfer bar" ignition and safety system to replace the old Colt rebounding hammer and safety block system.

In this new design a flat steel lever, or bar, would rise up between the frame mounted firing pin and the hammer when the trigger was pulled. When the hammer dropped, it struck the transfer bar which in turn struck the firing pin to transfer the force to the firing pin to ignite the cartridge.

This also acted as the safety system to prevent the revolver from firing unless the trigger was deliberately pulled.

In this new design, the hammer was made in such a way that it rests firmly against the frame when the action was at rest and could not physically touch the spring loaded firing pin in the frame at any time.

Since the hammer was made in such a way that it could not touch the firing pin, the gun could not fire unless the trigger was pulled to push the transfer bar upward between the firing pin and the hammer.

If a cocked gun were dropped, the transfer bar would be instantly snatched down and the firing pin couldn't be struck by the hammer.

If an un-cocked gun was dropped, the hammer was already resting against the frame and without the transfer bar in the upward position, the worst that could happen is that the hammer might break.

This new safety system was much simpler and even safer then the old Colt system, and was cheaper and easier to build since it required little hand fitting.

The new safety and ignition system so simple and revolutionary, virtually ever double action and most single action revolvers developed since has used a virtual copy of the Colt design.

While the new action was simpler and cheaper to build, Colt wanted to eliminate as much hand fitting as possible to further lower production costs.

To do that Colt decided to use a then new technology in the gun industry known as "sintered steel" manufacturing.

In this process powdered steel is injected into a mold and heated until the steel melts and fuses into a solid mass. When the mold is opened a nearly finished part is removed, needing only surface hardening and finishing.

Colt used sintered steel to make most of the internal parts of the new Mark III design, including the hammer and trigger, the cylinder locking bolt, and the hammer's double action strut.

In another industry first, Colt used stainless steel springs in the new design.

Since these parts could be produced very quickly and to a very tight tolerance, this allowed the new series to be assembled by less skilled assemblers.

The design of the new action was such that it was much less complicated than the old models and far less critical about the fit of parts,

To assemble one of these new revolvers, the assembler pulled a part from a bin and test fitted it. If the part didn't fit perfectly, he simply selected another part from the bin until one did fit. This drastically reduced the need for hand filing and stoning of parts by highly paid Master assemblers.

This made the Colt Mark III series the world's first "machine fitted" revolver.

Since these sintered steel parts were case hardened with a glass hard surface, this produced a very smooth, hard part that would wear well and give a very smooth operation.

Since the hardened surface is very thin, these new revolver could not have a traditional trigger or action job done in which internal parts are stoned and smoothed to make the action lighter or smoother. Because of the thin hardened surface any stoning or smoothing will break through the surface, exposing the softer metal inside. This ruins the parts since the exposed soft metal will wear quickly.

In this new design, any action or trigger work must be limited to installing a lighter spring kit.

MODELS

Since these new models would replace all old medium frame revolvers except the Python, Colt offered a wide range of versions.

The Mark III series was made from 1969 to 1983.

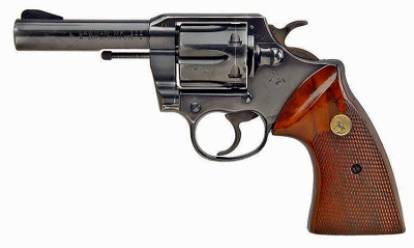

Trooper Mark III.

This was the premium model of the series. This was an adjustable sight, heavy shrouded barrel model fitted with Target grips, Target hammer, and Colt's first Target trigger.

Barrel lengths offered were 4 inches, 6 inches, and later in production, 8 inches.

Finishes were a new high gloss bright blue-black, bright nickel, and satin electroless nickel, also known as "Coltguard". This satin electroless nickel finish is often mistaken for stainless steel.

Calibers were .22LR, .22 Magnum, and .357 Magnum. A few Trooper Mark III's were special ordered by law enforcement in .38 Special.

Lawman.

The Lawman was a fixed sight Service type revolver.

It originally had a narrow, grooved Service type hammer and narrow grooved trigger. Later models used the same wide Target hammer as the Trooper Mark III.

Grips were originally narrow Service grips, but later production were often fitted with Target grips. Nickel and Coltguard finished guns came with Pachmayr "Signature" rubber grips with Colt medallions.

Barrel lengths were heavy 4 inch, and 2 inch. The early production 2 inch guns had the same exposed ejector rod as the 4 inch version, later production had a heavy, shrouded ejector rod barrel that made the gun look like a giant Detective Special. The 4 inch version retained the exposed ejector rod.

The 2 inch Lawman also had a rounded butt with special grips that were not used on any other Colt revolver.

Finishes were bright blue, bright nickel, and satin electroless nickel.

Caliber was .357 Magnum.

LAWMAN MARK III FOUR INCH

LAWMAN MARK III WITH LATER HEAVY, SHROUDED BARREL

LAWMAN MARK III WITH EARLY EXPOSED EJECTOR ROD

Metropolitan Police

The Metropolitan Police was simply a Lawman version offered only in .38 Special and with a 4 inch heavy barrel.

Bright blue finish.

METROPOLITAN POLICE, .38 SPECIAL

Official Police Mark III

The Official Police Mark III was another version of the Lawman only with the thin, "skinny" old Official Police type barrel fitted with a larger ramped front sight.

Caliber was .38 Special.

Barrel lengths were 4 inch, 5 inch, and 6 inch.

Finish was bright blue and bright nickel.

OFFICIAL POLICE MARK III

Officer's Model Match Mark III

This was intended to be the replacement for the Officer's Model series of target revolvers Colt had offered since 1905.

This was basically a Trooper Mark III with a vented 6 inch barrel and Patridge front sight and made in .38 Special.

There were only about 500 guns made before Colt dropped it. Most were shipped to Europe.

OFFICER'S MODEL MATCH MARK III

VARIATIONS

There were very few changes to the Mark III series over it's production life.

The first year or so, the Mark III had cylinders with counter-sunk chambers. Colt quickly changed this to a "fenced" cylinder in which there was a raised ring around the outer part of the cylinder to serve the same purpose as the counter-sunk chambers.

The 2 Inch Lawman early version had a heavy, exposed ejector rod type barrel, later changed to a heavy, shrouded ejector rod version.

Very late in production of the Trooper Mark III some revolvers had the vented rib barrel that was used on the Trooper Mark V.

MARK III "FENCED" CYLINDER.

Note the ring around the outer cylinder rim.

GRIPS

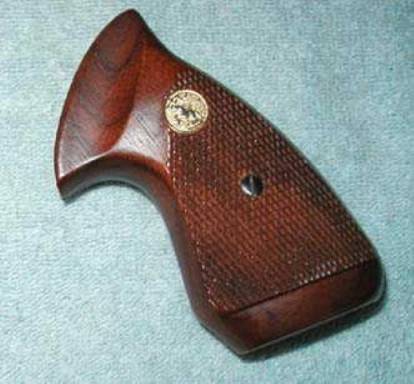

The new Mark III used a different grip frame that was not compatible with grips from the old type revolvers.

Mark III grips are not compatible and will not interchange with any other Colt revolver.

TARGET TYPE MARK III

These were used primarily on the Trooper Mark III but are found on later production of most other Mark III models

LATER PRODUCTION MARK III TARGET

Colt rounded off the butt of later production Target grips to make them more compact

SERVICE TYPE MARK III

These were used on most 4" Lawman, Metropolitan Police and Official Police Mark III versions.

LAWMAN MARK III 2 INCH BARREL VERSION

These were unique to the 2 inch Lawman Mark III

COMMERATIVE MARK III REVOLVERS

The following Commemorative models of the Mark III were issued by Colt:

Buckeye State Sheriff's Association 50th Anniversary. This was a Trooper Mark III, nickle finish, 4 inch barrel. 30 were made in 1981

Buckeye State Sheriff's Association 50th Anniversary. A Trooper Mark III, blue finish. 4 inch barrel. 170 made in 1981.

Immigration and Naturalization Service Diamond Jubilee Edition. A Trooper Mark III, 4 inch barrel. 300 made in 1981.